The Importance of Rebar Detailing in Construction Projects

In the realm of construction, particularly in the creation of reinforced concrete structures, the precision and accuracy of rebar detailing are paramount. Rebar Detailing involves the meticulous planning and execution of placing steel reinforcement bars (rebars) within concrete structures to ensure strength, stability, and longevity. This blog delves into the significance of rebar detailing in construction projects, exploring its components, tools, challenges, and prospects.

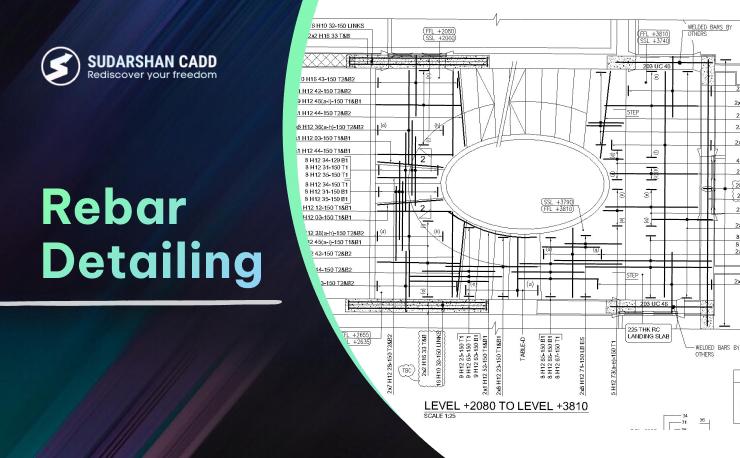

What is Rebar Detailing?

Rebar detailing is the process of creating detailed drawings and plans for the placement of reinforcement bars within concrete structures. These drawings serve as a blueprint for construction workers to follow, ensuring that the rebars are correctly positioned to provide maximum strength and durability to the structure. Rebar detailing encompasses the dimensions, quantity, spacing, and bending shapes of the rebars, tailored to meet specific structural requirements.

Importance of Accurate Rebar Placement in Reinforced Concrete Structures

Accurate rebar placement is crucial in reinforced concrete structures for several reasons:

- Structural Integrity: Properly placed rebars ensure the structure can withstand various loads and stresses, including tension, compression, and shear forces.

- Safety: Accurate rebar placement reduces the risk of structural failure, which can have catastrophic consequences, including loss of life and property.

- Durability: Correctly detailed and placed rebars enhance the longevity of the structure, making it more resistant to environmental factors such as corrosion and seismic activity.

- Cost Efficiency: Precise rebar detailing minimizes waste and optimizes the use of materials, leading to cost savings in both construction and maintenance.

Role of Rebar Detailing in Construction

Rebar Detailing Services play a pivotal role in the construction process, bridging the gap between design and execution. It translates complex engineering designs into actionable instructions for construction teams, ensuring that the structural elements are built as intended. Key roles of rebar detailing include:

- Facilitating Communication: Detailed rebar drawings provide a common reference for architects, engineers, and construction workers, promoting clear and effective communication.

- Ensuring Compliance: Rebar detailing ensures that the construction adheres to building codes, standards, and project specifications.

- Enhancing Efficiency: Accurate rebar detailing can make construction projects proceed more smoothly and efficiently, reducing the likelihood of errors and delays.

Key Components of Rebar Detailing

Effective rebar detailing involves several critical components:

Bar Bending Schedules (BBS)

Bar Bending Schedules (BBS) are comprehensive lists detailing the type, size, shape, and quantity of rebars needed for a construction project. They include precise bending instructions to ensure that each rebar is shaped correctly to fit the structural design. BBS helps in planning and procurement, ensuring that the right materials are available when needed.

Rebar Placement Drawings

Rebar Placement Drawings provide detailed visual guides indicating the exact locations, spacing, and arrangements of rebars within a concrete structure. These drawings ensure that construction workers know precisely where and how to place each rebar, optimizing the structural integrity of the project. Accurate placement drawings are crucial for maintaining the design’s strength and stability.

Cutting Lists

Cutting Lists are essential specifications that outline the lengths to which rebars need to be cut, minimizing waste and ensuring efficient use of materials. These lists help streamline the cutting process, making it easier to prepare rebars for placement. By adhering to cutting lists, construction teams can avoid material shortages and excesses, contributing to cost-effective project management.

Rebar Tags and Labels

Rebar Tags and Labels serve as identification markers for each rebar, facilitating easy identification and placement on site. These tags include crucial information such as the rebar type, size, and intended location within the structure. By using rebar tags and labels, construction teams can quickly and accurately place rebars, reducing errors and enhancing overall efficiency.

Tools and Technologies Used in Rebar Detailing

Modern rebar detailing relies heavily on advanced tools and technologies to enhance accuracy and efficiency. Two primary technologies used are:

- Building Information Modeling (BIM): BIM is a digital representation of a building’s physical and functional characteristics. It allows for the creation of detailed 3D models that include rebar placement, enabling better visualization and coordination.

- Computer-Aided Design (CAD): CAD software is used to create precise 2D and 3D drawings of rebar details, facilitating accurate planning and execution.

Overview of BIM (Building Information Modeling) and CAD (Computer-Aided Design)

Building Information Modeling (BIM)

BIM revolutionizes the construction industry by integrating data and workflows across the project lifecycle. In rebar detailing, BIM Services offers:

- 3D Visualization: Allows stakeholders to visualize the rebar placement in a 3D environment, identifying potential clashes and issues before construction begins.

- Collaboration: Enhances collaboration among architects, engineers, and contractors by providing a shared platform for information exchange.

- Data Management: Facilitates the management and retrieval of detailed information about each rebar, including specifications, quantities, and locations.

Computer-Aided Design (CAD)

CAD software remains a cornerstone of rebar detailing due to its precision and flexibility. Key benefits of CAD to BIM or CAD itself in rebar detailing include:

- Accurate Drafting: Provides tools for creating precise 2D and 3D drawings, essential for accurate rebar placement.

- Efficiency: Automates repetitive tasks such as generating bar bending schedules and cutting lists, saving time and reducing errors.

- Customization: Allows for the customization of rebar details to meet specific project requirements.

Challenges in Rebar Detailing

Despite its critical importance, rebar detailing faces several challenges:

- Complexity: The intricate nature of modern structures often makes rebar detailing a complex task, requiring high levels of precision and expertise.

- Coordination: Ensuring seamless coordination among various stakeholders, including architects, engineers, and contractors, can be challenging.

- Changes and Revisions: Construction projects often undergo changes and revisions, necessitating updates to rebar details, which can be time-consuming and prone to errors.

- Technological Integration: Integrating new technologies, such as BIM and CAD, into existing workflows requires investment and training.

Strategies for Overcoming Challenges

To address these challenges, the following strategies can be employed:

- Invest in Training: Regular training for personnel on the latest rebar detailing tools and techniques ensures that the team stays updated and proficient.

- Enhance Communication: Implementing robust communication protocols among stakeholders helps in minimizing misunderstandings and errors.

- Adopt Advanced Technologies: Leveraging BIM and CAD technologies enhances accuracy and efficiency, making it easier to manage complex projects.

- Implement Quality Control: Establishing rigorous quality control measures ensures that rebar details are checked and verified before implementation.

5 Tips for Effective Rebar Detailing in Revit

- Utilize Revit’s Rebar Tools: Use Revit’s built-in rebar tools to automate and streamline the detailing process.

- Integrate BIM Workflows: Incorporate BIM workflows to enhance collaboration and coordination among project stakeholders.

- Leverage 3D Modeling: Use 3D modeling capabilities to visualize rebar placement and identify potential issues early.

- Keep Up with Updates: Stay updated with the latest Revit versions and updates to take advantage of new features and improvements.

- Quality Assurance: Implement stringent quality assurance processes to ensure accuracy and compliance with project specifications.

Benefits of Effective Rebar Detailing

Effective rebar detailing offers numerous benefits:

Enhanced Structural Integrity

Accurate rebar detailing ensures that the structure is robust and capable of withstanding various loads and stresses, such as tension, compression, and shear forces. This precision in detailing leads to a more reliable and durable structure that can perform optimally under different conditions. Ultimately, it contributes to the long-term stability and safety of the construction.

Reduced Costs

Minimizing material wastage through precise rebar detailing optimizes resource use, leading to significant cost savings. By accurately calculating and specifying the required quantities of rebar, projects can avoid unnecessary expenses associated with over-ordering or rework. Efficient use of materials also reduces the construction process’s environmental impact.

Improved Efficiency

Accurate rebar detailing streamlines the construction process, reducing delays and minimizing the risk of errors. With clear and detailed instructions, construction teams can work more quickly and effectively, enhancing overall project timelines. This efficiency not only saves time but also ensures a smoother workflow on the construction site.

Increased Safety

Enhanced rebar detailing contributes to the overall safety of the structure, protecting both workers during construction and occupants afterward. Properly placed and secured rebars ensure that the structure can handle unexpected stresses and loads without compromising safety. This focus on safety reduces the risk of accidents and structural failures.

Compliance

Detailed rebar planning ensures that the construction adheres to relevant building codes and standards, which is critical for regulatory approval and project certification. Compliance with these standards guarantees that the structure meets all necessary safety and performance criteria, avoiding legal and financial repercussions. Adhering to codes also boosts the reputation and credibility of the construction team.

Enhanced Collaboration

Effective rebar detailing fosters better collaboration among architects, engineers, and construction teams by providing a clear and unified set of plans. This improved communication reduces misunderstandings and errors, ensuring that everyone involved in the project is on the same page. Enhanced collaboration leads to a more cohesive and successful construction process.

Sustainability

Accurate rebar detailing contributes to more sustainable construction practices by optimizing material usage and reducing waste. This not only lowers the project’s environmental footprint but also supports the use of recycled materials and eco-friendly methods. By focusing on sustainability, construction projects can achieve long-term benefits for both the environment and the community.

The Future of Rebar Detailing

The future of rebar detailing is poised for significant advancements driven by technological innovations and industry trends. Key trends to watch include:

- Automation: Increased automation in rebar detailing processes, reducing manual labor and errors.

- AI and Machine Learning: Integration of AI and machine learning to optimize rebar placement and improve efficiency.

- Enhanced BIM Capabilities: Continued evolution of BIM technologies, offering more advanced features for rebar detailing.

- Sustainability: Greater emphasis on sustainable construction practices, with rebar detailing playing a key role in resource optimization.

Unlock Precision: Rebar Detailing Services

Elevate your construction projects with expert rebar detailing from Sudarshan CADD. Ensure strength and accuracy in every build.

Conclusion

Rebar detailing is a critical aspect of construction projects, ensuring the strength, stability, and longevity of reinforced concrete structures. By leveraging advanced tools and technologies such as BIM and CAD and by implementing effective strategies to overcome challenges, construction professionals can enhance the accuracy and efficiency of rebar detailing. As the industry continues to evolve, staying abreast of technological advancements and industry trends will be essential for achieving optimal results in rebar detailing.

FAQ

What is meant by Rebar detailing?

Rebar detailing is the process of creating detailed drawings and schedules for the placement of reinforcement bars (rebars) within concrete structures to ensure structural integrity and compliance with design specifications.

What is the role of a rebar detailer?

A rebar detailer is responsible for creating detailed rebar placement drawings, bar bending schedules, and cutting lists. They ensure that rebars are accurately specified and positioned to meet the structural and safety requirements of a construction project.

What is rebar in detail?

A rebar, short for reinforcing bar, is a steel bar used to reinforce concrete and masonry structures. It enhances the tensile strength of the concrete, allowing it to withstand various loads and stresses.

What software is used for Rebar detailing?

Common software used for rebar detailing includes Building Information Modeling (BIM) tools like Autodesk Revit and Computer-Aided Design (CAD) software such as AutoCAD, which provide detailed 2D and 3D modeling capabilities.