Automotive Engineering

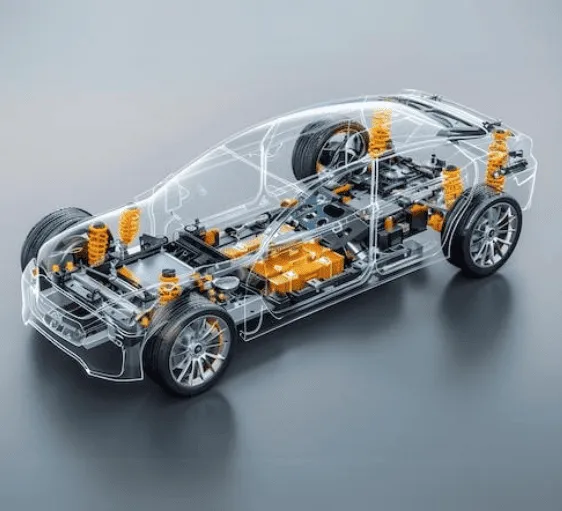

Automotive System Engineering

At SCADD, we have rich experience of providing the design solutions in automotive design engineering and Integration domain by performing complex engineering tasks under minimal supervision supporting the mission of clients.

We provide design support on all major aggregates of vehicle like engine installation, chassis, exhaust system, powertrain, cab Interior and exterior, piping and wiring harness routings and CAE validation.

Our Services

Automotive Design Experience:

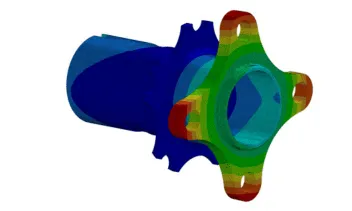

Experience in complete design project cycle like understanding project requirements, gather relevant standards, benchmarking, brainstorming, conceptualization, FEA/CFD for design optimization, customer reviews, risk mitigation plan, cross functional reviews with manufacturing, assembly, service, integration, and supplier.

Widely used “Six Sigma” tools/techniques like Boundary diagram, P-diagram, DFMEA, PUGH Matrix, Decision matrix, Critical parameter tree and DVPR

Experience in design toll-gate reviews

Worked in PLM process to release parts and drawings

GD&T for component, assembly and Tolerance stack-up analysis

Root cause analysis (RCA) of field failure projects

Dealing with suppliers for RFQ for the new part/component designed

Coordinating with prototype and testing team for tracking the failure issue

VA/VE, cost reduction, field failure and reliability projects

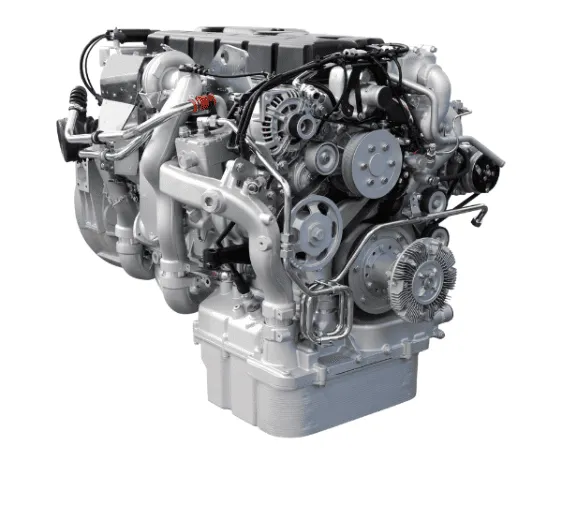

Diesel, Petrol and Gas engines design:

Engine integration and layouting of engine systems.

Rich experience in designing the engine systems: Coolant, Intake, Exhaust, Turbo charging, Fuel pump, Lubrication, Oil-sump, Gear train, EGR, Engine mount, Valve train, Cylinder head etc

Engine aftertreatment and emission control, DPF/SCR mounting on vehicle.

Experience in engine test requirements and performance parameters.

Tier 4 industrial, marine, locomotive and powergen application engine development

Chassis

Chassis system/subsystem/component design and mounting, frame design, loading calculations, coupling design, propeller shaft, SUPD/RUPD, spare wheel mounting, front and real axles. braking design and calculations, air cylinder mountings etc.

HVAC and Exhaust

Packaging of air intake system, cooling system, fuel line, and exhaust system.

Exhaust piping design and packaging, component mountings, and exhaust after treatment system installation.

Exhaust piping design and packaging, component mountings, and exhaust after treatment system installation.

CAB Exterior and Interior:

Sound experience in designing the surfaces including in A-class surface design for CAB exterior

Mounting of exterior components within the boundary as per vehicular agency standards.

Design plastic and sheet metal component like doors, hinges, mirrors, sun roof, outer panels etc.

Dashboard design, center console, seating systems, floor etc

Benefits of Automotive Engineering Service

Why Choose Us

Why choose SCADD for your automotive project?

SCADD stands out for automotive needs with deep expertise in engine design, covering Diesel, Petrol, and Gas engines. Offering complete design solutions, rigorous processes, and a focus on value and efficiency, SCADD ensures reliable, client-focused results. Trust SCADD for collaborative design support across all vehicle systems

Deep Expertise in Engine Design & Systems

Complete Automotive Design Solutions

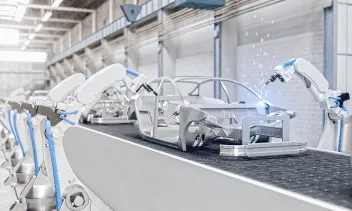

Rigorous Design & Manufacturing Processes

Proven Problem-Solving & Supplier Management

Focus on Value & Efficiency

Collaborative & Client-Focused Approach

FAQ

What are automotive engineering services?

Automotive engineering services encompass a range of solutions provided by engineering firms to support the design, development, testing, and manufacturing of vehicles.

What specific areas do automotive engineering services cover?

These services include design and simulation, prototype development, testing and validation, manufacturing support, supply chain management, and regulatory compliance.

Can automotive engineering services help with electric vehicles (EVs) and autonomous vehicles (AVs)?

Yes, engineering firms specializing in automotive services often offer expertise in EV and AV technologies, including battery design, autonomous systems integration, and software development.

How do automotive engineering services ensure quality and safety?

Through rigorous testing, simulation, and validation processes, these services help manufacturers meet stringent quality and safety standards, ensuring reliability and minimizing risks for end-users.