Rapid Prototyping

What Is Rapid Prototyping?

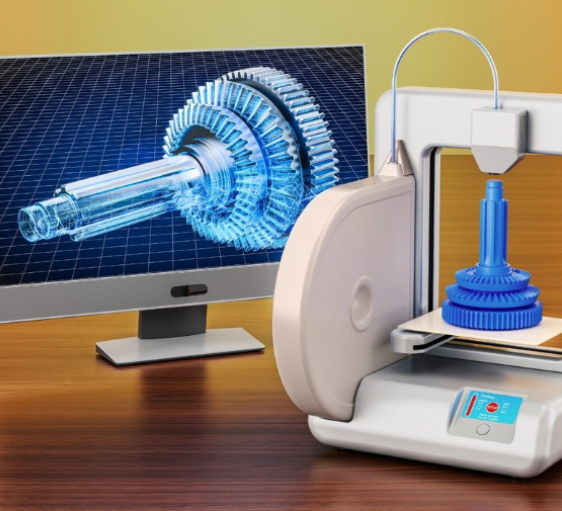

Rapid prototyping is a method of quickly creating a scale model or prototype of a physical part or assembly using 3D computer-aided design (CAD) data. It allows for the rapid iteration and testing of design concepts before full-scale production, helping to identify and address potential issues early in the development process.

Stuck on a new product idea? Bring it to life! Our expert Rapid Prototyping Services bridge the gap between imagination and reality. We craft physical models fast, allowing you to see, touch, and test your designs before committing to production. Let's turn your vision into a tangible success story.

Stuck on a new product idea? Bring it to life! Our expert Rapid Prototyping Services bridge the gap between imagination and reality. We craft physical models fast, allowing you to see, touch, and test your designs before committing to production. Let's turn your vision into a tangible success story.

How Rapid Prototyping Services Differ From Traditional Approach?

Overall, rapid prototyping offers significant advantages over traditional prototyping methods in terms of speed, cost, complexity, customization, material selection, iterative process, and accessibility. These differences contribute to its growing popularity and widespread adoption in various industries.

Rapid prototyping allows for much faster iteration cycles compared to traditional methods.

Rapid prototyping typically involves lower costs compared to traditional prototyping methods.

Rapid prototyping offers greater flexibility for customization

Rapid prototyping allows for a wider range of materials to be used in the prototyping process

Rapid prototyping enables the creation of highly complex and intricate designs with relative ease.

Unlocking Efficiency and Precision

How to Choose Right Types!

Types of Rapid Prototype Techniques

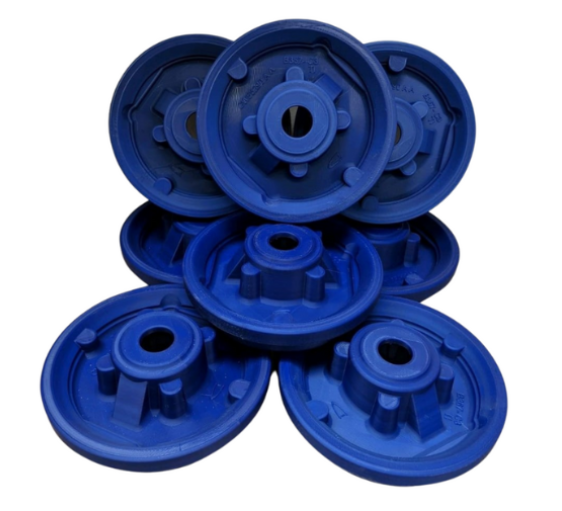

Our Rapid Prototyping Services

3D printing

Functional prototyping

Presentation model

Proof of concept

Alpha & Beta build

Aesthetic prototype

Benefits of Rapid Prototyping Services

Our Milestone With Rapid Prototyping

500

+

Repeat Business

100

+

Global Client

350

+

Completed Projects

20

+

Countries Served

WHY CHOOSE US

Why Choose Us For Your Rapid Prototyping Solutions?

Skip prototype delays! Sudarshan CADD Tech brings your brainwaves to market in days, not weeks. Our expert engineers, state-of-the-art equipment, and streamlined process turn ideas into reality, fast.

Accurate models using high end 3D printers

Fast turnaround of the projects tasks

Partnering with quality product manufacturers

Quality check and in-house testing facility

Accurate drawing documentation

Better utilization of resources

FAQ

What is rapid prototyping?

Rapid prototyping is a process used in product development to quickly create physical prototypes of a design concept. It involves using computer-aided design (CAD) software and additive manufacturing technologies, such as 3D printing, to produce prototypes rapidly and cost-effectively.

What are the different types of rapid prototyping technologies?

There are several rapid prototyping technologies available, including stereolithography (SLA), selective laser sintering (SLS), fused deposition modeling (FDM), digital light processing (DLP), and selective laser melting (SLM). Each technology has its advantages and limitations in terms of materials, resolution, speed, and cost.

What are some common applications of rapid prototyping?

Rapid prototyping is used across various industries and applications, including product design and development, engineering and manufacturing, medical device prototyping, architectural modeling, aerospace and automotive prototyping, and consumer electronics prototyping.

What are the advantages of rapid prototyping over traditional prototyping methods?

Some advantages of rapid prototyping over traditional prototyping methods include faster turnaround times, lower costs for small-batch production, greater design flexibility, reduced material waste, and the ability to produce complex geometries that are difficult or impossible to achieve with traditional methods.

What are some limitations or challenges of rapid prototyping?

Some limitations or challenges of rapid prototyping include limitations in material selection and properties, limited accuracy and resolution compared to traditional manufacturing methods, post-processing requirements for certain technologies, and challenges in scaling up production for mass manufacturing.