Design Validation

Design Validation Services & Engineering Simulation

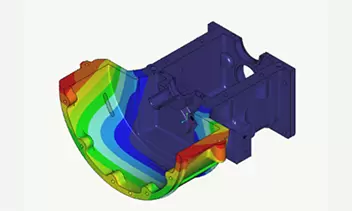

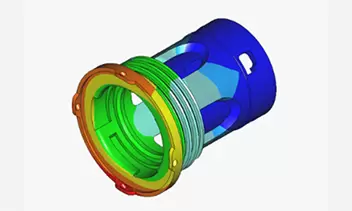

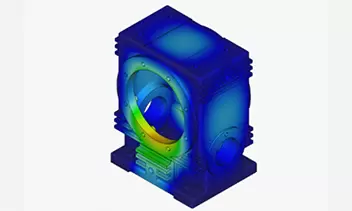

Turning ideas into flawless products takes two things: expert Design Validation Services and insightful analysis. We help manufacturers and designers achieve just that with comprehensive FEM consulting. From stress and fatigue analysis to heat and pressure evaluation, we ensure your product is built to thrive. Think of us as your engineering backbone, silently supporting every step of the journey from concept to creation.

Why Is Engineering & Design Validation Services Important?

Engineering validation is a critical process in product development that ensures the accuracy, functionality, safety, and compliance of engineering designs. It involves testing and analyzing components, systems, or processes to verify that they meet specified requirements, standards, and regulations.

Engineering & Design validation is important for several key reasons:

Quality Assurance

Compliance with Regulations and Standards

Cost Efficiency

Competitive Advantage

Regulatory Compliance

Reliability Assessment

Performance Evaluation

Compatibility Testing

Values

What We Do For Design Validation

Design Validation Services

Static Analysis

Dynamic Analysis

Flow Analysis

Thermal Analysis

Benefits of Design Validation services

Our Mileston & Experience

500

+

Repeat Business

100

+

Global Client

350

+

Completed Projects

20

+

Countries Served

Our Dedicated Work Experience

Imagine testing your product virtually before it’s built! This approach merges creative exploration with real-world simulations, predicting how your product will perform throughout its lifespan. Think of it as a crystal ball for your design, revealing potential issues and optimizing every step.

WHY CHOOSE US

Why Choose Us For Design Validation Services?

We help manufacturers and designers bring their fluid-carrying creations to life. Our expert FEM analysis covers everything from strength and heat transfer to wear and tear, ensuring your structures perform flawlessly.

Save cost of doing iterations

Save prototyping and manufacturing cost

Launch your product faster in the market

Better utilization of resources

FAQ

What is a validation design?

A validation design is a process of confirming that a product meets its intended use and requirements.

What is DVP in automotive?

DVP in automotive stands for "Design Validation Plan," which outlines how a product's design will be validated to ensure it meets performance and quality standards.

What is design validation FDA?

Design validation FDA refers to the validation of medical device designs to ensure they meet FDA regulatory requirements for safety and efficacy.

What is the difference between design verification and design validation?

The difference between design verification and design validation is that verification confirms if the design outputs meet the design inputs, while validation confirms if the design meets user needs and intended use requirements.